It is tricky to “see” and thus “show” the value… clients keep numbers hidden. And NDA does not allow to show the details…

However, some conservative estimates can be made from observing the situation. Here, for example, a team of 2 people was working for 3 months. And “designed” a “solution” that failed. Spectacularly failed. Their component (designed with another consultant) just bent and the rod touched the floor…

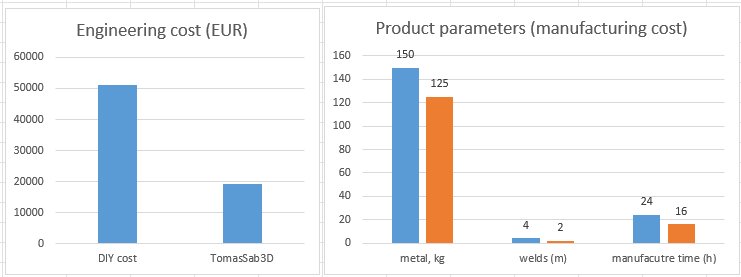

Instead of 3 months, it took me 3 weeks alone to do it. The resulting product was not only performing correctly, but also cost less to manufacture:

Mass 30% lower, less raw material needed.

CNC machine friendly geometries - less cutting time.

Welding length reduced by 200%… again - faster to manufacturing time.

Ergonomic design… it is very common that a component “optimized” for the loads has a certain “professional look” to it.

As a result… not only did the client save more than 2x on the time it takes to engineer “a real, working solution”. They also ended up with a product that is 30% cheaper in raw material, nearly 2x faster to manufacture, and comes with CE marking compatible documentation and parametric tables - to show to their clients.

All in 3 weeks.

TomasSab3D.com